Scottish Water and its PFI partners use 199GWh of gas and fuel oil per year.

The majority of the gas is used in the thermal drying and processing of wastewater sludge.

Fuel oil is used for standby generation of power at our assets in the event of power supply problems.

The remaining gas is used for heating in our buildings.

This leads to 38ktCO2e per annum.

2019/20 POSITION

GAS AND FUEL

OIL USED

TOP 4 CONTRIBUTORS TO GAS AND FUEL CONSUMPTION

WASTEWATER SLUDGE

DRYING AT DALDOWIE

SLUDGE PROCESSING

AT SEAFIELD

STANDBY

GENERATION

3%

HEATING

BUILDINGS

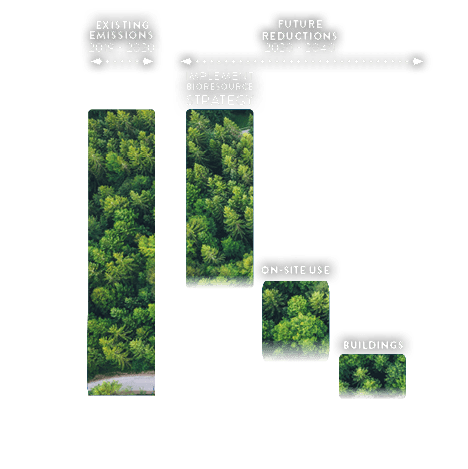

MAXIMISE ENERGY

RECOVERED FROM

BIORESOURCE

REDUCE

CONSUMPTION

OF FUEL OIL

REDUCE USE

OF GAS

These tables illustrate the key activities we are

exploring to reduce our gas and fuel oil emissions.

We will keep these under review

with our expert advisory panel.

These tables illustrate the key activities we are

exploring to reduce our gas and fuel oil emissions.

UP TO

2025

• Consider rationalisation of buildings post COVID-19.

UP TO

2030

UP TO

2040

• Identify, assess and implement activities to replace sludge drying technology and alternatives to gas for sludge processing.

• Delivery of new solution at Daldowie to maximise value of bioresource.

• Maximise renewable generation from bioresource.

• Identify, assess and implement activities to maximise value of bioresource at returning PFI assets.

• Identify, assess and implement alternative technologies to replace standby generation on our assets (e.g. battery power).

• Complete implementation

of alternative technologies

to replace standby generation on our assets.

• Identify, assess and implement renewable heat sources for our buildings.

• Complete implementation of renewable heat sources for our buildings.

• Deliver Juniper House refurbishment as a net zero emissions building.

UP TO

2025

• Consider rationalisation of buildings post COVID-19.

• Identify, assess and implement activities to replace sludge drying technology and alternatives to gas for sludge processing.

• Identify, assess and implement alternative technologies to replace standby generation on our assets (e.g. battery power).

• Identify, assess and implement renewable heat sources for our buildings.

• Deliver Juniper House refurbishment as a net zero emissions building.

UP TO

2030

• Delivery of new solution at Daldowie to maximise value of bioresource.

• Identify, assess and implement activities to maximise value of bioresource at returning PFI assets.

• Complete implementation of alternative technologies to replace standby generation on our assets.

• Complete implementation of renewable heat sources for our buildings.

UP TO

2040

• Maximise renewable generation from bioresource.

DEVELOP ALTERNATIVE FUEL

FOR SLUDGE PROCESSING

DEVELOP ALTERNATIVE TECHNOLOGIES

TO STANDBY GENERATION

DEVELOP ZERO

EMISSIONS BUILDINGS

DEVELOP ALTERNATIVE FUEL FOR SLUDGE PROCESSING

DEVELOP ALTERNATIVE TECHNOLOGIES TO STANDBY GENERATION

DEVELOP ZERO EMISSIONS BUILDINGS

INNOVATION

CHALLENGES

DEVELOP ALTERNATIVE FUEL

FOR SLUDGE PROCESSING

DEVELOP ALTERNATIVE TECHNOLOGIES

TO STANDBY GENERATION

DEVELOP ZERO

EMISSIONS BUILDINGS

KEY ENABLER TO SUPPORT REDUCING

GAS AND FUEL OIL EMISSIONS

EXTERNAL FACTORS THAT SUPPORTS

REDUCING GAS AND FUEL OIL EMISSIONS

UK GAS NETWORK TRANSITION

from natural gas to biomethane

and hydrogen for heating

INTRODUCTION

TRANSFORMATION

ELECTRICITY

PROCESS

EMISSIONS

GAS &

FUEL OIL

TRANSPORT

& TRAVEL

INVESTMENT

STORING

CARBON

Scottish Water has established a framework for the supply of sustainably sourced hydrotreated vegetable oil that can be used by both Scottish Water and its construction partners. It’s a drop in fuel replacement that reduces emissions by 90% compared to conventional diesel.

Over the last year it has been widely adopted by our construction partners, displacing diesel use in excavators, cranes and other heavy plant. It is also being used to fuel generators to provide power for remote construction sites.

On our water mains rehabilitation programme its adoption is expected to reduce emissions by nearly 30%.