WHERE ARE WE NOW?

Scottish Water invests £700m pa to maintain and improve our services.

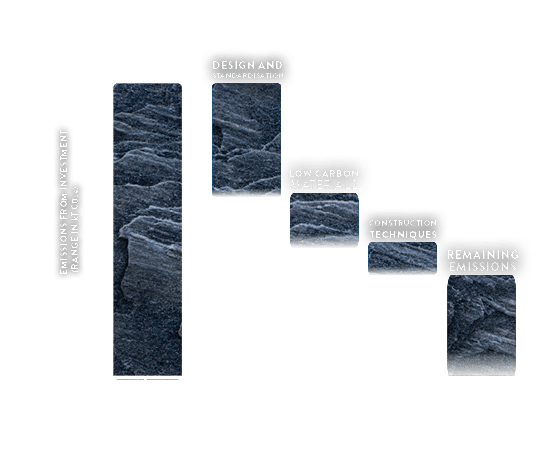

We are growing our understanding of investment emissions and have developed a new measure – the carbon intensity of investment that we will work to reduce. Our current view of this is 200-300 tCO2e/£m.

2019/20 POSITION

£700m

INVESTED

PER YEAR

200-300tCO2e

PER MILLION POUND CARBON

INTENSITY OF INVESTMENT

TOP 5 CONTRIBUTORS

TO INVESTMENT EMISSIONS

CIVIL

ENGINEERING

INFRASTRUCTURE

MECHANICAL AND ELECTRICAL

SITE

TEMPORARY

WORKS

REDUCE

CARBON INTENSITY

OF INVESTMENT

ZERO

EMISSION DESIGNS

LOW CARBON

MATERIALS

LOW CARBON

CONSTRUCTION

These tables illustrate the key activities we are

exploring to reduce our investment emissions.

These tables illustrate the key activities we are exploring to reduce our investment emissions.

UP TO

2025

• Establish Construction Expert Panel to bring external knowledge and innovation support.

UP TO

2030

• Low carbon construction expertise is embedded throughout Scottish Water delivery teams.

UP TO

2040

• Applying circular economy principles, our decision support tools promote low emission options.

• All projects assess and report the emissions impact of their construction and operation.

• All programmes and projects are aiming to reduce emisisons.

• All projects routinely demonstrate they have minimised emissions as far as possible.

• We improve availability of emissions data of products and services to support low emission investment decisons.

• Common data reporting of emissions across all products and services supports low emission choices.

• We develop engineering specifications, with learning from other sectors, to deliver net zero emissions assets.

• Engineering specifications continually adopt innovation and learning from other sectors to deliver net zero assets.

• We will develop a design library with proven and standard low emission designs.

• We continually update our design library with proven and standard low emission designs.

• Delivery and supply chain partners are engaged and contractually incentivised to deliver emissions reduction.

• Delivery and supply chain partners embrace low carbon innovation and lead in developing and adopting best practice.

• All programmes and projects are able to demonstrate net zero emissions over the life of the asset.

UP TO

2025

• Establish Construction Expert Panel to bring external knowledge and innovation support.

• Applying circular economy principles, our decision support tools promote low emission options.

• All projects assess and report the emissions impact of their construction and operation.

• We improve availability of emissions data of products and services to support low emission investment decisons.

• We develop engineering specifications, with learning from other sectors, to deliver net zero emissions assets.

• We will develop a design library with proven and standard low emission designs.

• Delivery and supply chain partners are engaged and contractually incentivised to deliver emissions reduction.

UP TO

2030

• Low carbon construction expertise is embedded throughout Scottish Water delivery teams.

• All programmes and projects are aiming to reduce emisisons.

• Common data reporting of emissions across all products and services supports low emission choices.

• Engineering specifications continually adopt innovation and learning from other sectors to deliver net zero assets.

• We continually update our design library with proven and standard low emission designs.

• Delivery and supply chain partners embrace low carbon innovation and lead in developing and adopting best practice.

UP TO

2040

• All projects routinely demonstrate they have minimised emissions as far as possible.

• All programmes and projects are able to demonstrate net zero emissions over the life of the asset.

UP TO

2025

• With our supply chain we will identify and assess the top 10 emission intensive construction materials and promote low/zero emission alternatives.

UP TO

2030

• Progress development of low and zero emission construction materials.

UP TO

2040

• Adopt emerging new low and zero emission construction materials.

• Supply chain engaged in assessing emissions in its own supply chain; seeking low emission products.

• Supply chain procures low and zero emissions materials as standard.

• Our supply chain develops decision support tools to enable low emission designs and construction.

• Our supply chain applies decision support tools to enable low emission designs and construction.

• Promote offsite fabrication and no dig designs to reduce time, emissions and waste on sites applying circular economy principles.

• Offsite fabrication and no dig designs adopted as standard to reduce time, emssions and waste on site.

UP TO

2025

• With our supply chain we will identify and assess the top 10 emission intensive construction materials and promote low/zero emission alternatives.

• Supply chain engaged in assessing emissions in its own supply chain; seeking low emission products.

• Our supply chain develops decision support tools to enable low emission designs and construction.

• Promote offsite fabrication and no dig designs to reduce time, emissions and waste on sites applying circular economy principles.

UP TO

2030

• Progress development of low and zero emission construction materials.

• Supply chain procures low and zero emissions materials as standard.

• Our supply chain applies decision support tools to enable low emission designs and construction.

• Offsite fabrication and no dig designs adopted as standard to reduce time, emssions and waste on site.

UP TO

2040

• Adopt emerging new low and zero emission construction materials.

DEVELOPMENT OF EMISSION

FREE MATERIALS

DEVELOPMENT OF EMISSION

FREE CONSTRUCTION TECHNIQUES

DEVELOPMENT OF EMISSION

FREE PLANT AND EQUIPMENT

INNOVATION CHALLENGE

DEVELOPMENT OF

HYDROGEN VEHICLES.

INNOVATION

CHALLENGE

DEVELOPMENT OF EMISSION

FREE MATERIALS

DEVELOPMENT OF EMISSION

FREE CONSTRUCTION TECHNIQUES

DEVELOPMENT OF EMISSION

FREE PLANT AND EQUIPMENT

KEY ENABLERS TO SUPPORT

REDUCING INVESTMENT EMISSIONS

DATA AND INFORMATION

on emissions in products

and services

CONSTRUCTION PARTNERS

work with us to deliver reduction of carbon intensity of investment

DECISION MAKING

building emissions into our decision making processes

PROCUREMENT

enabling procurement of low

and zero emission materials

PEOPLE CAPABILITY

develop low and zero emissions

design and construction skills

KEY ENABLERS TO SUPPORT

REDUCING INVESTMENT EMISSIONS

DATA AND INFORMATION

on emissions in products

and services

CONSTRUCTION PARTNERS

work with us to deliver reduction of carbon intensity of investment

DECISION MAKING

building emissions into our decision making processes

PROCUREMENT

enabling procurement of low

and zero emission materials

PEOPLE CAPABILITY

develop low and zero emissions

design and construction skills

EXTERNAL FACTORS THAT SUPPORT

REDUCING INVESTMENT EMISSIONS

REGULATORY GOVERNANCE

and decision making fully represents the emissions impacts and benefits from all investment choices

MATERIAL AVAILABILITY

Availability of zero emissions materials and plant for supply chain

EXTERNAL FACTORS THAT SUPPORT REDUCING INVESTMENT EMISSIONS

REGULATORY GOVERNANCE

and decision making fully represents the emissions impacts and benefits from all investment choices

MATERIAL AVAILABILITY

Availability of zero emissions materials and plant for supply chain

INTRODUCTION

TRANSFORMATION

ELECTRICITY

PROCESS

EMISSIONS

GAS &

FUEL OIL

TRANSPORT

& TRAVEL

INVESTMENT

STORING

CARBON

Scottish Water has established a framework for the supply of sustainably sourced hydrotreated vegetable oil that can be used by both Scottish Water and its construction partners. It’s a drop in fuel replacement that reduces emissions by 90% compared to conventional diesel.

Over the last year it has been widely adopted by our construction partners, displacing diesel use in excavators, cranes and other heavy plant. It is also being used to fuel generators to provide power for remote construction sites.

On our water mains rehabilitation programme its adoption is expected to reduce emissions by nearly 30%.

Scottish Water has been a partner in a project, led by the local community and supported by the National Lottery’s Community Fund, to regenerate the site once occupied by Douglas Primary School as a multi-functional greenspace.

Our team worked with the community to incorporate sustainable drainage features in the new park, which store and slowly release the rainwater that falls on surrounding roads and rooftops during storms. This eases pressure on the combined sewer network in the local area, as well as helping to protect the local environment and reduce flood risk from the Dighty Burn. Importantly, the community has been able to realise its wider aims by creating an attractive outdoor space that also provides a home for wildlife; and can be enjoyed for play, relaxation, exercise, events and the growing of food.

Planning is now underway to introduce more sustainable water management measures in the area surrounding the park, with the aim of disconnecting over 40,000m2 of land area from the combined sewer network; and helping to enable the development of more social housing in Douglas. Engagement with the community, including schools and other key stakeholders, is being carried out to help shape the proposals.

Work with the community and Dundee City Council on sustainable drainage for Douglas has helped to inspire the Water Resilient Dundee partnership. This initiative is now pursuing opportunities for more sustainable management of stormwater across the city, reducing flood risk in communities, creating capacity for development and enhancing amenity.