In the slightly altered words of Elvis, our mantra in the world of Capital Investment has been: “a little less conversation, a little more climate action.”

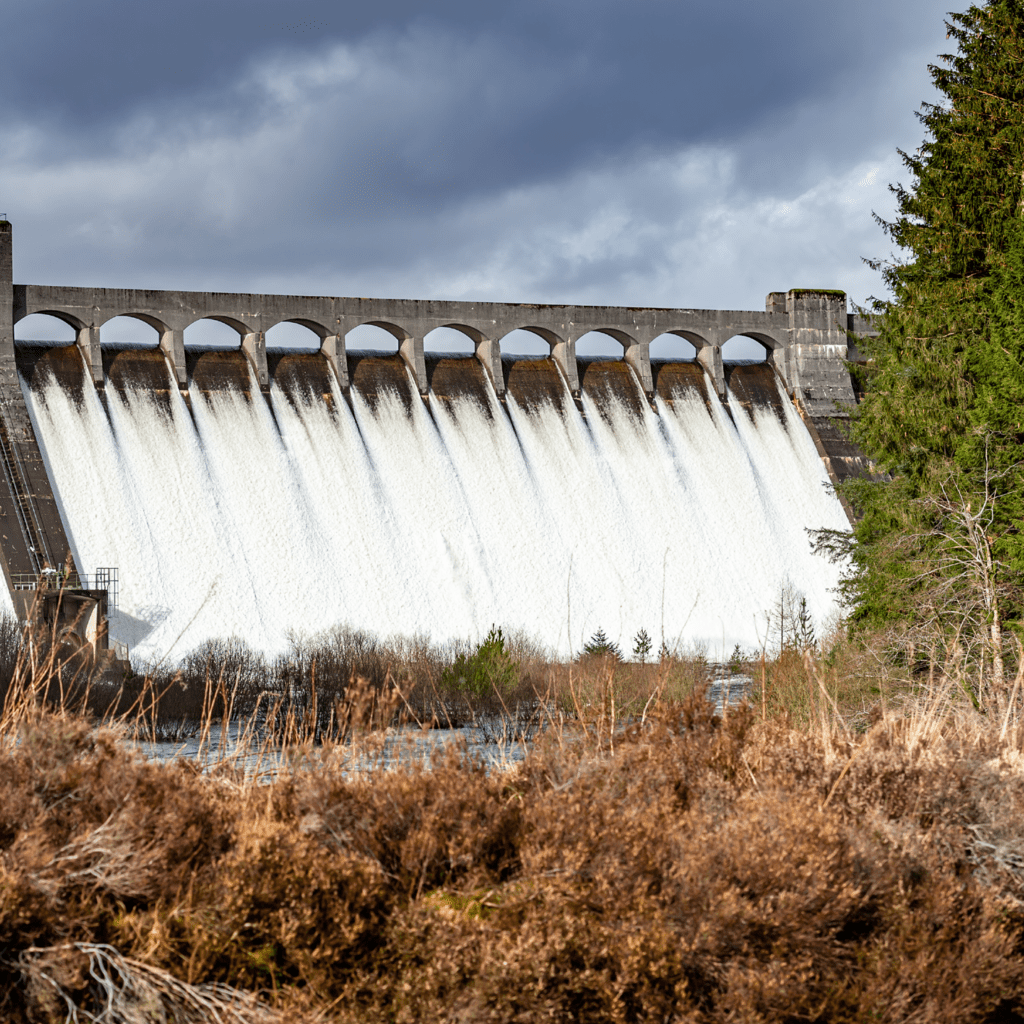

Our routemap to net zero marks its first anniversary and it has been a good time to reflect on not just how much we have learned in Scottish Water and our supply chain partners, but what is being delivered on the ground.

Our business knowledge has increased. On the capital programme we have learned that on average there are around 200-300 tonnes of embedded carbon for each £1m invested.

We have signed up to reducing this by 75% by 2032. We know that we need to think differently and go after the lowest whole life carbon solutions. We need to change how we design projects, procure materials, and carry out construction.

We established an ‘expert panel’ for reduction in carbon in construction and it has explored many issues to grow knowledge and drive action. It is attended by senior reps from all of our supply chain, CECA (the Cilvil Engineering Contractors Association) and Scotland’s construction innovation centre. So, all the right people are there to help shift the dial.

One fantastic output is the ‘Carbon Academy’ – our digital learning hub. It’s available across our supply chain as well as to employees and will help us reach net zero but importantly go beyond thereafter.

Our Alliance partners have mapped their top 10 materials which drive emissions: at the top end of the list are concrete and steelwork; so to materials which help from our pipelines – so important to our day-to-day service for customers.

Here are some examples which are making a small but important dent in carbon emissions:

Procurement: All our suppliers have committed to create carbon plans by 2023.

Pilot Projects: 16 projects are identified in Managed Delivery to pilot low emission materials/techniques. CWA and ESD have published case studies of the use of golden rules.

Concrete: Two trials of low carbon concrete are underway, the first in Scotland.

Diesel: Hydrated vegetable oil (HVO) offering 90% reduction in emissions is being piloted by one of our delivery partners. Another has trialled innovative new software monitoring plant and material movements in real time to reduce movement and emissions.

Pipe Materials: Modified approach to selection – brought to life by new materials avoiding the need for concrete thrust blocks on our largest pipeline project.

Net zero site establishment: CWA’s site at Ibrox has been set up using net zero cabins involving solar panels and rainwater collection, wider deployment is being explored.

Net zero plant and equipment: We have successfully trialled electric mini diggers

Many construction sites use diesel generators for all their power. We are working with the supply chain to trial alternative approaches and fuels for generation to reduce emissions.